Exxel Objects is an International Strategic Sourcing Specialist for Electrical, Instrumentation, Mechanical, and Process Equipment, as well as Spare Parts and Key Bulk Materials, across a number of Industries and Geographies.

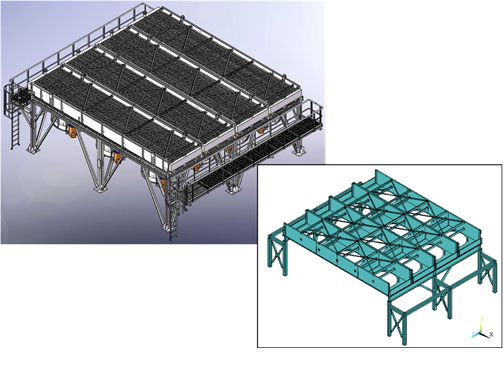

Exxel Objects is also an Engineering Solutions provider for Skid Mounted Packages to the Oils and Gas Industry and an Engineering Solutions Provider for Modular Units to the Data Center Market.